Our Transfer Finishes

Transfer finish and embellishment facts

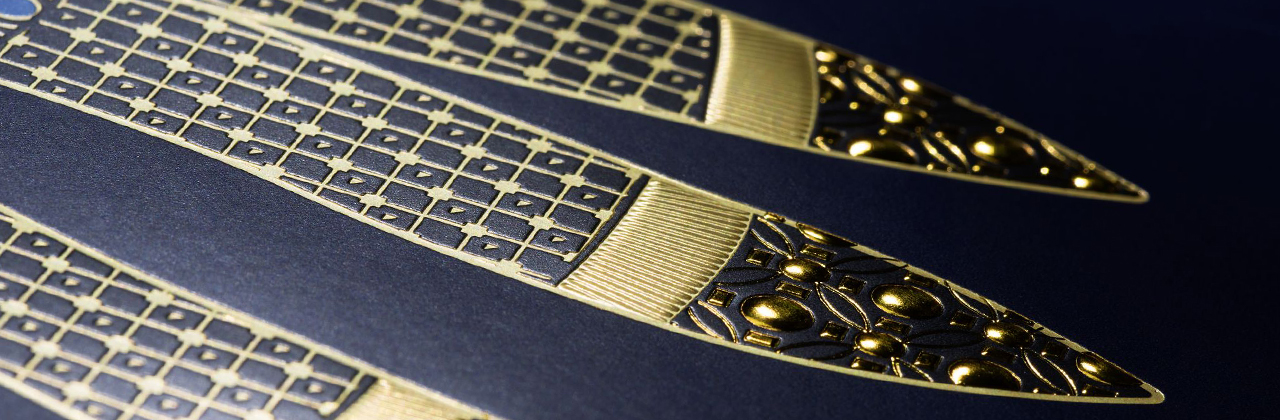

Excellent Finishing with Slimmest Material Costs

At KURZ, our work is committed to the sparing use of natural resources. This involves, first and foremost, minimization of the raw materials used:

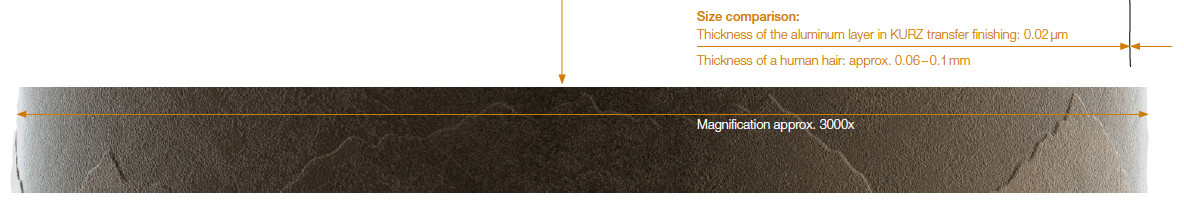

KURZ transfer coating is the slimmest decoration process with the lowest material requirement in the world. With a layer thickness of only 1.5–3 μm, our applications account for only one percent by mass of your total product, be it plastic, paper, or cardboard.

We employ only ecologically harmless materials and do not use ozone-depleting, halogenated hydrocarbons, chrome (VI), cadmium, lead or mercury. We apply our designs only in dry, wastewater-free processes like hot stamping, and cold- and digital transfer. Our decorations are thus 80 percent less carbon-intensive and easily recycled and deinked.

Reliably Protected: Transfer-finished Packaging

Comparing KURZ transfer finishing to other decoration processes clearly reveals that the wafer-thin aluminum layer makes the decoration of packaging with KURZ transfer technology extremely efficient and resource conserving. A minimum of material and application suffice for a premium look – glossy, edge-defined and more, with an unrivaled range of designs.

Minimum Application – Maximum Sustainability Effect

Transfer-finished packaging can be recycled

Paper and cardboard decorated with KURZ transfer finishing can be recycled without restriction by existing collection, sorting and recycling machinery. Every type of KURZ finished product can be recycled without additional expense.

Learn more about transfer finishing in the recycling loop.

Transfer-finished packaging is biologically degradable and compostable

When it comes to the biological degradability and compostability of packaging, KURZ transfer decoration has been proven safe. For example, LUXOR® MTS 220 is certified according to DIN EN 13432 as an additive that is harmless for the composting process. The minimal decorative layer (≤ 1% by weight) does not affect the process. The Requirement: The cardboard itself is compostable (disintegration test for DIN EN 13432).

Recycling Reliability for Automotive and Plastic Decoration

As a Global Player, we believe it's on us to leave a better world for subsequent generations. We conduct research on products and processes for a closed recycling loop. Our goal is to offer customers freedom of design at maximum efficiency. Teaming up with you, we develop trend-setting plastic decorations which do not affect the recyclability of your products and give you a sustainable, competitive edge.

Our products can now finish recycled material with the same high quality and creativity as virgin material. Do you want to rise above the rest with highly appealing innovations in sustainability? Check out our solutions at our parallel site www.plastic-decoration.com. We will help you thrill your customers with innovative ideas and sustainability, all without lowering your sights.

Create Want with Sustainable Design

With our solutions you will expand your expertise in sustainability, and boost brand loyalty:

- Durable finishing of your products

- Recyclability of components

We use dry chromium-plating, for instance, instead of electroplating. This considerably reduces your CO2 footprint:

- Conservation of resources

- Lower your CO2 footprint by up to 95%

We use as much renewable energy as possible, generated with our own solar systems:

- 100% solar energy at sites in Germany

- Global environmental standards

Environmentally Relevant Information about Stamping Foils

Stamping foils represent no hazardous materials due to the Ordinance on Hazardous Substances (11/2010). According to REACH they have to be classified as articles (1907/2006/EG) and therefore are no subject to registration. KURZ does not use any raw materials containing volatile, ozone depleting halogenated hydrocarbons, cadmium, lead, mercury or hexavalent chromium for the stamping foil production.

The vast majority of our stamping foils fulfill the requirements of the various national and international regulations, taking into consideration their formulations, the specifications provided by raw material suppliers and their usage in their respective specialized applications.

For more environmentally relevant information about our products, please contact us.

Conflict minerals

In regards to requirements stipulated in the Dodd-Frank Act (Section 1502 – "Conflict Minerals"), KURZ continues to work with our suppliers to trace raw material content determining whether minerals from mines or uncertified melting plants located in conflict regions are utilized.

No conflict minerals originating in the Democratic Republic of Congo and adjoining countries are intentionally used for the manufacturing of KURZ products. To meet this requirement, we oblige our suppliers to supply written due diligence and explicit prove of the source of their materials for our raw material production. Furthermore, they are required to confirm the origin of material contents classified as conflict minerals..

Information from LEONHARD KURZ Stiftung & Co. KG on the "Reclassification of Titanium Dioxide"

Get information about the new classification of Titanium Dioxide by the European Commission and its impact on KURZ transfer finishing products here.

How to use Titanium Dioxide (TiO2)?

As a universal white pigment, Titanium Dioxide has been used for decades in paints and coatings, for products such as toothpaste and sunscreen, in adhesives, plastics and even as a food additive.

What does the reclassification of Titanium Dioxide mean?

After lengthy discussions at EU level, the European Commission adopted the 14th adaptation of the CLP Regulation as Delegated Regulation (EU) 2020/217 on October 4, 2019, which was published in the Official Journal of the European Union on February 18, 2020. This Regulation will enter into force on 9 March 2020 and must be implemented by 9 September 2021 at the latest.

The Regulation classifies Titanium Dioxide as carcinogenic (suspect substance, category 2) in powder form with at least 1 % particles of aerodynamic diameter ≤ 10 µm and introduces additional EUH statements.

- The classification applies only to pure Titanium Dioxide powder and to all powder products containing at least 1 % Titanium Dioxide in particle form or incorporated in particles with an aerodynamic diameter ≤ 10 µm in the mixture.

- It does NOT apply to products, i.e. articles such as wallpaper, paper or transfer products containing titanium dioxide.

Is Titanium Dioxide contained in KURZ transfer products?

In principle, KURZ transfer products can contain Titanium Dioxide. The Titanium Dioxide is bound in a solid matrix and is therefore an insoluble component of the transfer material, even after application to the end product.

Wallpaper and finished plasters, for example, are not affected by this classification either, because there also Titanium Dioxide is incorporated and fixed in a solid matrix.

Do KURZ transfer products have to be labeled additionally?

The additional labeling according to EUH212 for mixtures containing ≥ 1 % Titanium Dioxide particles, as required by the Regulation, is not applicable for our transfer products, but only for solid or liquid mixtures (e.g. powder coatings, paints).

Our transfer products are classified as articles under the EU Regulation 1907/2006 of 18.12.2006 (REACH VO) and are therefore not subject to registration. The preparation of a safety data sheet is therefore not mandatory for our KURZ transfer products.